Have you ever been in the middle of a sewing project when suddenly your needle breaks? It can be frustrating and can bring your progress to a halt. But fear not! In this article, we’ll explore some quick and easy steps to take when your sewing machine needle breaks. With these tips, you’ll be back to sewing in no time!

Sewing machine needles can break for a variety of reasons, from using the wrong needle for the fabric to sewing over pins. But don’t worry, it’s a common occurrence and can be easily fixed. In this article, we’ll discuss the steps you can take to handle a broken needle and get back to your sewing project without any major setbacks.

Causes of a Sewing Machine Needle Breaking

When you’re in the middle of a sewing project and your needle suddenly breaks, it can be frustrating and disruptive. But don’t worry, needle breakage is a common occurrence and can be easily fixed. Let’s explore some of the possible causes of a sewing machine needle breaking:

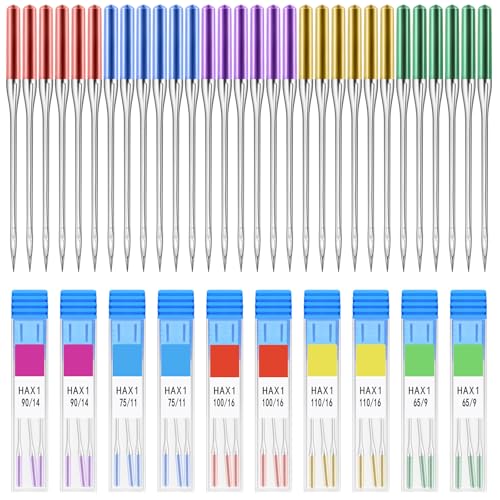

1. Incorrect Needle Type or Size

Using the wrong needle for your fabric can put unnecessary stress on the needle, leading to breakage. Make sure you’re using the correct needle type and size for the fabric you’re working with. Check your machine’s manual for guidance on which needle types and sizes are recommended for different fabrics.

2. Dull or Damaged Needle

A dull or damaged needle can easily break while sewing. Needles can become dull after extended use or if you accidentally hit a pin while sewing. Replace your needle regularly to avoid breakage and ensure clean stitching.

3. Incorrect Needle Insertion

Incorrectly inserting the needle into your sewing machine can cause it to break. Make sure the flat side of the needle is facing the back and that it is fully inserted and tightened. Double-check your machine’s manual for proper needle insertion instructions.

4. Sewing Machine Timing

If your machine’s timing is off, it can cause the needle to hit the bobbin or other machine parts, resulting in breakage. Have a professional technician check and adjust your machine’s timing if you suspect this is the issue.

5. Sewing at High Speeds

Sewing at high speeds, especially with thick or dense fabrics, can place excessive strain on the needle and cause it to break. Slow down your sewing speed when working with challenging fabrics to reduce the risk of needle breakage.

Remember, a broken needle is not a major setback. By identifying and addressing the cause of the breakage, you can quickly get back to your project. Always keep a supply of spare needles on hand, as well as a needle threader for easy replacement of broken needles. Happy sewing!

Next, let’s discuss how to safely remove a broken needle from your machine.

Signs That Your Sewing Machine Needle is Broken

When you’re knee-deep in a sewing project, the last thing you want is for your trusty sewing machine needle to break. It can be frustrating, but don’t worry – it happens to the best of us. The good news is that recognizing the signs of a broken needle is the first step in quickly getting back to sewing without any major setbacks. Here are some key signs that your sewing machine needle is broken:

- Stitching Problems: Do you notice irregular stitches, skipped stitches, or uneven tension on your fabric? These are common signs that your needle is on its last legs. A broken needle can’t smoothly penetrate the fabric, resulting in stitching problems. So if your stitches are acting up, it’s time to inspect your needle.

- Unusual Sounds: Did you hear a loud clanging noise or a sudden pop? That’s your needle breaking! Sometimes, you might even hear a strange grinding or scraping sound while sewing. These odd noises are a clear indication that your needle is broken and needs to be replaced.

- Fabric Snags: If you notice your fabric being snagged or pulled down into the machine, you can bet that your needle is broken. When a needle breaks, it can catch the fabric, causing it to get entangled around the needle or inside the machine. Stop sewing immediately and proceed with caution.

- Visible Damage: Take a closer look at your needle. Do you see any visible signs of damage, such as a bent or misshapen tip? A broken needle is often quite obvious, so trust your eyes to confirm if your needle needs to be replaced.

Steps to Take When a Sewing Machine Needle Breaks

When a sewing machine needle breaks, it can be frustrating and disruptive to your sewing project. But fear not! As an expert in all things sewing, embroidery, knitting, and crafts in general, I’m here to guide you through the steps to take when this happens.

- Stay Calm: First things first, don’t panic! Remember, a broken needle is a common occurrence, and it can be easily fixed.

- Identify the Cause: The next step is to identify what caused the needle to break. Some possible reasons include using the incorrect needle type or size, having a dull or damaged needle, incorrect needle insertion, sewing machine timing issues, or sewing at high speeds.

- Consult Your Manual: To correctly address the issue, I always recommend consulting your sewing machine’s manual. It provides valuable information specific to your machine and can guide you on how to handle a broken needle.

- Replace the Needle: Once you’ve determined the cause, it’s time to replace the needle. Make sure to have a supply of spare needles handy, as it’s always a good idea to have backups. Use a needle threader to easily insert the new needle.

- Check Other Components: While you’re at it, take a moment to inspect other components of your machine, such as the bobbin, presser foot, and thread tension. Ensure they are in proper working order to prevent any further issues.

- Resume Sewing: With everything back in place, it’s time to resume your sewing project. Remember to slow down your sewing speed when working with challenging fabrics to reduce the chances of another broken needle.

By following these steps, you’ll be able to handle a broken sewing machine needle like a pro. Remember, practice makes perfect, and the more familiar you become with your machine, the better equipped you’ll be to handle any mishaps that come your way.

How to Safely Remove a Broken Needle from a Sewing Machine

When a sewing machine needle breaks, it can be a frustrating setback in the middle of a project. But fear not! I’m here to guide you through the process of safely removing a broken needle from your sewing machine, so you can get back to sewing in no time.

Here’s what you need to do:

- Power off the machine: The very first step is to turn off your sewing machine and unplug it from the power outlet. Safety should always come first when dealing with a broken needle.

- Locate the needle screw: Look for the needle screw or clamp that holds the needle in place. It is generally located near the needle area or underneath the needle plate. Consult your machine’s manual if you’re unsure.

- Loosen the needle screw: Gently loosen the needle screw using a screwdriver or the appropriate tool. Be cautious not to damage any other parts of the machine while doing so.

- Remove the broken needle: Once the screw is loose, carefully remove the broken needle from the machine. Avoid pulling or forcing it out, as this can cause damage to the needle hole or other components.

- Check for any remaining needle fragments: Take a moment to inspect the machine and ensure that there are no remaining fragments of the broken needle. If you spot any, carefully remove them using a pair of tweezers or needle-nose pliers.

- Clean the needle area: Use a soft brush or a lint-free cloth to clean the needle area and remove any loose threads or debris. This will help prevent any potential blockages or obstructions in the future.

That’s it! You’ve successfully removed the broken needle from your sewing machine. Remember to dispose of the broken needle safely by placing it in a sharps container or a designated needle disposal container.

Now that you know how to safely remove a broken needle, let’s move on to the next section, where we’ll discuss the signs that indicate a broken needle, so you can spot the issue early on and avoid any more needle mishaps.

Tips for Preventing Sewing Machine Needle Breakage

Sewing machine needle breakage can be frustrating and disruptive to your sewing projects. However, with some simple precautions, you can minimize the chances of it happening. Here are some expert tips to help you prevent sewing machine needle breakage:

- Choose the right needle for your fabric: Use the appropriate needle type and size for the fabric you are working with. Different fabrics require different needle sizes and styles to ensure smooth sewing. For example, use a ballpoint needle for knits and a sharp needle for woven fabrics. Choosing the right needle will reduce the risk of it breaking.

- Check the needle quality: Inspect your needles regularly for any signs of damage or wear. Bent or dull needles are more likely to break. It’s recommended to change your needle after every 8-10 hours of sewing or sooner if you notice any issues.

- Thread correctly: Ensure that you thread your machine correctly, following the manufacturer’s instructions. Proper threading prevents the needle from getting caught or bending, which can lead to breakage.

- Check for burrs or rough spots: Occasionally, the needle plate, throat plate, or bobbin area can develop burrs or rough spots. These can cause the needle to break. Check these areas regularly and use a fine-grit emery board to smooth out any rough spots.

- Adjust the tension: Incorrect tension can put unnecessary stress on the needle, leading to breakage. Check your machine’s manual for instructions on adjusting the tension and ensure it is set correctly for your fabric and thread.

- Slow down and avoid excessive force: Sewing too fast or with too much force can put strain on the needle, causing it to break. Take your time and let the machine do the work.

- Clean and maintain your machine: Regularly clean the bobbin area and lint build-up from your machine. A clean machine runs smoother and reduces the risk of needle breakage.

Conclusion

Now that you’re equipped with the knowledge and tips provided in this article, you can confidently handle a broken sewing machine needle without any major setbacks. Remember, needle breakage is a common occurrence and can happen for various reasons, but it’s nothing to worry about.

« Discover the Secret Needle Size That Will Transform Your Quilting Projects

Discover the Ultimate Guide to Choosing the Best Embroidery-Free Sewing Machine – Don’t Miss Out »

By following the steps outlined in this article, you can safely remove a broken needle from your machine and dispose of it properly. Additionally, the expert tips provided will help you prevent future needle breakage and ensure smooth sewing projects.

Always remember to choose the right needle for your fabric, check the needle quality, thread correctly, and regularly clean and maintain your sewing machine. These simple practices will go a long way in preventing needle breakage and keeping your machine in top condition.

So, the next time your sewing machine needle breaks, don’t panic. Just refer back to this article for quick and easy solutions. Happy sewing!