Ever wondered why your sewing machine suddenly starts skipping stitches or producing uneven seams? It might be time to change your needle. Sewing machine needles don’t last forever, and their lifespan can vary depending on the fabric you’re using and how often you sew.

Understanding when to replace your needle can save you a lot of frustration and keep your projects looking professional. Whether you’re a seasoned seamstress or just starting, knowing how long your needles last is essential for smooth and efficient sewing. Let’s dive into what affects needle longevity and how you can tell when it’s time for a change.

Understanding Sewing Machine Needle Longevity

Understanding how long sewing machine needles last can ensure smooth and efficient sewing projects. Needle longevity depends on various factors and recognizing signs of wear helps you avoid issues.

Factors That Influence Needle Lifespan

Several factors affect how long a sewing machine needle lasts:

- Fabric Type: Heavier fabrics, like denim and canvas, wear out needles faster than lighter fabrics, like cotton and silk.

- Sewing Time: Prolonged use reduces needle lifespan. Professionals may need to change needles more frequently.

- Stitch Type: Embroidery or zigzag stitches can strain the needle more than straight stitches.

- Needle Quality: High-quality brands typically last longer than inexpensive options.

- Thread Quality: Using high-quality thread minimizes abrasion and extends needle life.

Signs It’s Time to Change Your Needle

Recognizing when to change your needle is crucial for maintaining sewing quality:

- Skipped Stitches: If your machine starts skipping stitches, the needle may be dull or bent.

- Puckering Fabric: Puckering or pulling of fabric can indicate a worn needle.

- Unusual Noises: Strange noises during sewing could mean the needle is damaged.

- Thread Breakage: Frequent thread breakage often points to a blunt or bent needle.

- Visible Damage: Bent or blunt needles should be replaced immediately.

Keep these factors and signs in mind to maintain effective sewing and ensure your projects turn out beautifully.

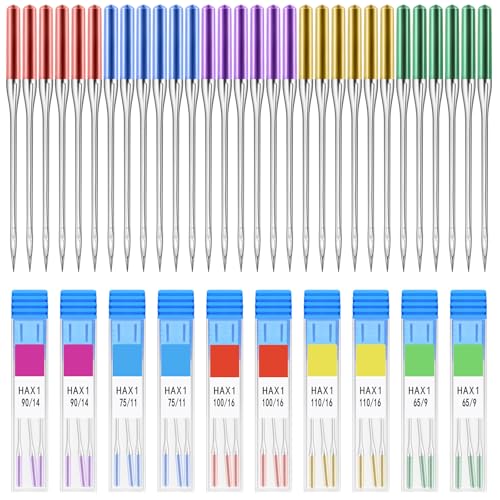

Different Types of Sewing Machine Needles

Knowing the different types of sewing machine needles helps you choose the right one for your projects. The type of needle impacts the quality of your stitching, especially when switching between different fabrics and threads.

Universal Needles

Universal needles fit standard sewing projects using woven or knitted fabrics. These needles have a slightly rounded tip, making them versatile for various tasks. Sizes range from 60/8 to 120/19. Size 70/10 works for light fabrics like cotton, while size 90/14 suits medium-weight fabrics like linen. Universal needles are reliable options for general sewing without requiring frequent changes.

Specialty Needles for Specific Fabrics

Specialty needles cater to fabric-specific needs, ensuring precise stitching and preventing damage.

- Ballpoint Needles: Designed for knit fabrics, these needles have rounded tips that glide between fabric threads without causing runs.

- Jeans Needles: With strong shafts and sharp points, these needles penetrate thick fabrics, like denim and canvas, without bending.

- Microtex Needles: Thin and sharp, these needles handle delicate fabrics like silk and microfiber, resulting in clean and precise stitches.

- Embroidery Needles: These needles have larger eyes and a narrower shaft to accommodate embroidery threads, reducing thread breakage.

- Quilting Needles: Designed for layers of fabric and batting, these needles have tapered points, providing smooth stitching without skips.

Consider your fabric and project type when selecting your needle. This ensures optimal performance and extends needle life.

Maintenance Tips to Extend Needle Life

Extending needle life involves proper maintenance and attention.

Proper Installation

Install the needle correctly to avoid damage. Ensure the flat side faces the right direction, typically toward the back. Insert it fully into the needle clamp and tighten the screw securely. Use pliers if needed for a firmer grip. An improperly installed needle can break easily or cause sewing issues.

Regular Cleaning

Clean your sewing machine regularly to prevent debris buildup. Lint, thread, and fabric particles can accumulate in the needle area, causing needles to dull faster. Use a small brush or vacuum attachment to remove dust. Wipe the needle bar with a lint-free cloth. Do this cleaning after every project or at least once a week if you sew frequently.

Common Mistakes That Shorten Needle Life

Using Incorrect Needle Type

Choosing the wrong needle type for your fabric drastically reduces needle lifespan. Needles designed for lightweight fabrics can’t handle heavy-duty materials like denim, which leads to premature breakage. Always match the needle type to the fabric you’re sewing.

Sewing Over Pins

Leaving pins in the fabric while sewing frequently snaps or bends needles. This not only damages the needle but can also harm your machine. Remove pins before they reach the needle’s path to prolong needle life.

High Stitch Speed

Consistently sewing at maximum stitch speed subjects needles to excessive strain, causing them to dull or break quickly. Moderate your stitching speed to avoid overworking your needles.

Using Damaged Needles

Continuing to use bent or dulled needles worsens their condition and can damage your fabric. Regularly inspect needles and replace them at the first sign of damage to maintain optimal performance.

Neglecting Regular Cleaning

Failing to clean your sewing machine leads to debris buildup, causing needles to dull faster. Regularly clean your machine, especially the needle area, to prevent unnecessary wear.

Improper Needle Installation

Incorrectly installed needles can result in them bending or breaking. Ensure proper alignment and secure fitting when installing new needles in your sewing machine.

« Discover the Remarkable Legacy: How Long Has ‘Sewing with Nancy’ Been Inspiring Sewers?

Can You Cook with Sewing Thread? Discover the Surprising Culinary Uses and Safety Tips »

Low-Quality Threads

Using low-quality or old threads can cause lint accumulation and additional friction, which dulls needles rapidly. Opt for high-quality threads to ensure smooth stitching and longer needle life.

Sewing Through Thick Seams

Forcing needles through thick seams without changing to a suitable needle type results in bending or breaking. Switch to a heavier needle when working on dense sections to avoid this issue.

Each of these common mistakes can diminish the effectiveness and lifespan of your sewing machine needles. By avoiding them, you ensure longer-lasting needles and more efficient sewing projects.

Conclusion

Keeping an eye on your sewing machine needle’s condition can make a world of difference in your sewing projects. By understanding the factors that affect needle longevity and recognizing signs of wear you can ensure smoother and more efficient sewing. Remember to choose the right needle for your fabric and avoid common mistakes like sewing over pins or neglecting regular maintenance. With these tips you’ll enjoy longer-lasting needles and better results in all your sewing endeavors. Happy sewing!