Ever wondered why some fabrics hold their shape better than others or why certain areas of a garment feel a bit stiffer? That’s where sewing interfacing comes into play. Interfacing is a hidden gem in the sewing world, providing structure and stability to fabric, making your handmade creations look polished and professional.

Understanding Sewing Interfacing

Interfacing is critical in sewing, offering structure and stability to fabrics. It helps achieve a professional finish by firming up areas like collars, cuffs, and waistbands.

Types of Interfacing

Interfacing comes in different forms, depending on your project needs.

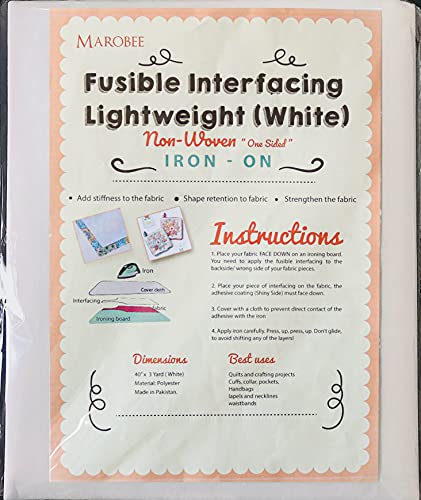

- Fusible Interfacing: This type has a glue on one side that bonds to the fabric when heated with an iron. It’s easy to apply and commonly used in everyday sewing.

- Sew-in Interfacing: Without glue, this type requires stitching to the fabric. It’s ideal for thicker or heat-sensitive materials.

- Knit Interfacing: Made from knit fabric, this type stretches with the garment, making it perfect for knit fabrics that need more flexibility.

- Woven Interfacing: Similar to regular fabric, this type doesn’t stretch and adds firmness without altering fabric properties.

- Non-woven Interfacing: Made from fibers bonded together, this type is versatile and can be used with various fabric types. It’s suitable for crafts, bags, and certain apparel areas.

Choosing the Right Interfacing

Selecting the appropriate interfacing ensures the best results for your sewing project.

- Fabric Type: Match the interfacing with your fabric. Use knit interfacing for stretchy fabrics and woven interfacing for stable ones.

- Weight: Choose interfacing that matches the fabric’s weight. Light interfacing for lightweight fabrics prevents bulkiness, and heavy interfacing for sturdy fabrics provides adequate support.

- Project Requirements: Consider the interfacing’s role in your project. Fusible interfacing can be quicker to apply for large projects, while sew-in interfacing excels in precision-required tasks.

- Care Instructions: Check if the interfacing aligns with your fabric’s care instructions. Some may not withstand washing or high heat.

Using the right interfacing can elevate your sewing projects, making your creations look polished and professional.

How Interfacing Is Used in Sewing

Interfacing plays a critical role in various sewing projects. By reinforcing and shaping the fabric, interfacing ensures your finished piece looks polished and professional.

Reinforcing Fabric

Interfacing adds stability to fabric areas needing extra support. It’s vital for collars, cuffs, and waistbands, where fabric endures stress. For instance, using fusible interfacing on a collar helps it stand up crisply instead of flopping over. It’s also used to back lightweight fabrics, preventing distortion during sewing. Choose the right type for your fabric to maintain its integrity and appearance.

Shaping and Structure

Interfacing gives shape to parts of your projects, such as bag handles and hat brims. When adding interfacing, the fabric gains the desired form without sagging. For example, sew-in interfacing is often used in tailored blazers to keep the lapels sharp and structured. It also creates a smooth, wrinkle-free surface, enhancing the overall quality of your work. By deciding the right level of stiffness, your pieces stand out with clean and precise silhouettes.

Feel confident using interfacing to elevate your sewing projects, whether you’re working on clothing, accessories, or crafts.

Tips for Working With Interfacing

Enhancing your sewing projects with interfacing can elevate the quality of your finished pieces. Follow these helpful tips to ensure your interfacing is perfectly integrated.

Cutting and Attaching Interfacing

Cut interfacing pieces accurately to match your fabric pieces. Place the interfacing on the wrong side of the fabric, ensuring it lines up precisely. For fusible interfacing, use medium heat and a damp pressing cloth when ironing. Press, don’t glide, the iron to prevent shifting. For sew-in interfacing, baste or pin in place before stitching. Always follow the manufacturer’s instructions for interfacing application to achieve the best results.

Common Mistakes to Avoid

Avoid incorrect interfacing type for fabric. Match the interfacing weight to the fabric weight for proper support. Avoid insufficient pressing time for fusible interfacing by pressing according to the manufacturer’s recommendations, ensuring complete adhesion. Refrain from cutting interfacing on the bias unless the project specifies this, which can cause distortion. Avoid ignoring grainlines. Cutting with grainlines ensures the shape and integrity of your project.

By following these tips, you can seamlessly integrate interfacing into your sewing projects, enhancing the overall quality and durability.

The Importance of Interfacing in Fashion Design

Interfacing is a crucial component in fashion design, providing both functional and aesthetic benefits to garments.

Impact on Clothing Durability

Interfacing enhances the durability of clothing by adding extra support to areas under stress. Collars, cuffs, and waistbands are reinforced, preventing wear and tear. This support helps maintain the garment’s shape, ensuring it holds up well over time. For instance, fusible interfacing can add stiffness to a shirt’s collar, preventing it from becoming floppy after multiple washes. Proper selection of interfacing prolongs the life of your creations.

Enhancing Aesthetic Appeal

Interfacing improves the aesthetic appeal of garments by providing structure and stability. It helps fabrics maintain a crisp, clean appearance, essential for tailored items like jackets and blazers. For example, non-woven interfacing can be used in a dress bodice to create a smooth, pleasing silhouette. You can achieve precise lines, sharp edges, and professional finishes by incorporating the right type of interfacing. This results in polished, high-quality projects that stand out.

Integrating interfacing into your designs ensures both durability and a refined look, elevating the overall quality of your handmade pieces.

Conclusion

Understanding and using interfacing can truly transform your sewing projects. By adding structure and stability, interfacing helps you achieve that polished, professional look you’re aiming for. Whether you’re working with collars, cuffs, or waistbands, the right interfacing can make all the difference.

Remember to choose the type that best suits your fabric and project needs. With a little practice, you’ll find that interfacing not only enhances the durability and shape of your garments but also elevates their overall aesthetic appeal. Happy sewing!