Are you frustrated with your sewing machine? Do you find yourself constantly facing issues and not knowing how to fix them? Well, you’ve come to the right place! In this article, we’ll explore common problems that people encounter with their sewing machines and provide you with simple and effective solutions. Whether it’s a jammed needle, tangled thread, or uneven stitches, we’ve got you covered. So, let’s dive in and get your sewing machine back up and running smoothly again!

Is your sewing machine giving you a hard time? Don’t worry, you’re not alone. Many people experience difficulties with their sewing machines, but the good news is that most problems can be easily resolved. In this article, we’ll walk you through some of the most common sewing machine issues and give you practical tips on how to troubleshoot and fix them. From tension problems to bobbin thread snags, we’ll help you get to the root of the problem and get your sewing machine back in action.

Sewing enthusiasts know that a malfunctioning sewing machine can be a real buzzkill. Whether you’re a beginner or an experienced seamstress, dealing with sewing machine problems can be frustrating. But fear not! In this article, we’ll address some of the most common issues that can arise with your sewing machine and provide you with step-by-step solutions. So, if you’re tired of dealing with broken needles, skipped stitches, or noisy motors, keep reading to find out how to troubleshoot and fix these problems with ease.

Understanding the Issue with Your Sewing Machine

One of the most frustrating things about sewing is when your machine starts giving you trouble. But fear not! As an expert in all things sewing, embroidery, knitting, and crafts in general, I’m here to guide you through understanding and fixing the issues with your sewing machine. So, let’s dive right in!

When it comes to troubleshooting your sewing machine, the first step is to identify the problem. Here are a few common issues you might encounter and how to tackle them:

1. Tension Troubles: Uneven or loose stitches can be a result of tension issues. Start by rethreading both your upper and bobbin thread, ensuring they are securely in place. Remember to check that your tension settings are appropriate for the fabric you’re using. If that doesn’t work, try adjusting the tension dial slightly until you achieve the desired stitch.

2. Bobbin Thread Snags: Are you experiencing snags or tangles with your bobbin thread? This could be due to improper bobbin placement. Make sure the bobbin is inserted correctly, with the thread feeding in the correct direction. If the issue persists, check for any burrs or sharp edges on the bobbin case that may be causing snags. Smooth them out using an emery board if necessary.

3. Broken Needles: A broken needle can interrupt your sewing flow and even damage your fabric. If you encounter this issue, start by turning off your machine and replacing the broken needle with a new one. Remember to use the correct needle type and size for your specific project. Additionally, double-check that your needle is inserted correctly and secured tightly.

4. Skipped Stitches: Skipped stitches can be frustratingly visible on your finished product. First, ensure that the needle is brand new and properly inserted. Next, check the tension and stitch length settings. If the issue continues, try using a different thread or adjusting the fabric’s position as you sew to ensure it is properly feeding through the machine.

5. Noisy Motor: Is your sewing machine creating more noise than music to your ears? Start by checking for any loose screws or parts that may be causing vibrations. If you find any, tighten them gently. Also, make sure your machine is clean and free from lint or debris that may be interfering with its smooth operation. Regular maintenance and oiling can help keep the motor running quietly.

Understanding the issues with your sewing machine

Common Problems Faced by Sewers

Sewing machines are incredible tools that make our crafting projects easier and more efficient. However, like any machine, they can encounter problems from time to time. In this section, we will explore some common issues that you might face with your sewing machine and offer practical solutions to resolve them.

Tension Problems

One of the most common problems sewers encounter is tension issues. If you notice loose or tight stitches, uneven stitches, or thread bunching up on the fabric, there may be a problem with the tension settings on your machine. Check that the thread is properly threaded in the tension discs and adjust the upper tension dial as needed.

Bobbin Thread Snags

Another frustrating problem is when the bobbin thread keeps snagging or tangling. This can lead to messy stitches and an overall poor stitching experience. First, clean the bobbin area and remove any lint or tangled thread. Then, ensure that the bobbin is properly inserted and threaded correctly. Also, make sure that you are using the correct bobbin size for your machine.

Broken Needles

It’s not uncommon for a needle to break while sewing, especially if you’re working with thick or heavy fabrics. Replace the broken needle with a new one that matches the fabric and thread weight you’re using. Remember to insert the needle correctly, with the flat side facing the back of the machine.

Skipped Stitches

If you’re noticing skipped stitches in your sewing, there are a few possible culprits. Ensure that the needle is properly inserted and tightened. Also, check if the needle is dull or bent – if it is, replace it. Additionally, clean the feed dogs and check that the fabric is correctly aligned and tensioned as you sew.

Noisy Motors

If your sewing machine is making loud or unusual noises, it may be a sign of a problem. First, check for any loose screws or parts and tighten them if necessary. Clean and oil the machine regularly to keep the motor running smoothly. If the noise persists, it may be best to consult a professional for further diagnosis and repair.

Diagnosing the Problem with Your Machine

Is your sewing machine giving you trouble? Don’t worry, we’re here to help you diagnose the problem and get your machine back on track. Whether you’re a sewing enthusiast or a beginner, it’s common to encounter issues with your machine from time to time. So, let’s dive into the most common problems and find out how to fix them!

Tension Problems

Are you noticing uneven stitches or loose threads? The culprit might be a tension problem. First, check the tension settings on your machine – make sure they’re properly adjusted. Next, rethread your machine, ensuring that the thread is correctly placed in the tension discs. Finally, test your machine using different fabrics to ensure the tension is consistent.

Bobbin Thread Snags

« Discover the Surprising Benefits of Easy Sewing Projects for the Elderly! You Won’t Believe What They Can Achieve

Shocking! Discover the Terrifying Consequences When a Dog Swallows a Sewing Needle »

Is the bobbin thread constantly snagging or getting tangled? This can be frustrating, but it’s often an easy fix. Clean the bobbin area, removing any lint or thread bits that may be causing the issue. Next, check the bobbin itself – ensure it’s wound correctly and placed correctly in the bobbin case. If all else fails, try using a different thread – sometimes a poor-quality thread can cause issues.

Broken Needles

Are your needles breaking frequently? This can happen for a variety of reasons. First, double-check that you’re using the correct needle type and size for your project and fabric. Inspect the needle for dullness or bending – a damaged needle can cause breakage. Also, make sure the needle is inserted correctly and tightly screwed into place. If the issue persists, consider replacing the needle or contacting a professional for further assistance.

Skipped Stitches

Are you experiencing skipped stitches in your sewing projects? This can be caused by several factors. Start by checking your needle – make sure it’s not damaged or dull. If the needle is fine, clean the feed dogs – they may be clogged with lint or debris. Additionally, rethread the machine and ensure the fabric is properly positioned under the presser foot. These simple steps should help resolve the issue.

Noisy Motors

Is your sewing machine making strange noises? This can be alarming, but there’s usually a simple solution. First, check for any loose screws or parts – tighten them if necessary. Next, **clean and oil your machine regularly

Checking the Needle and Thread Tension

When it comes to sewing, having the correct needle and thread tension is crucial for achieving smooth and even stitches. If you’re experiencing tension problems with your sewing machine, don’t worry – I’ve got you covered!

Here’s what you can do to check and adjust the needle and thread tension:

- Inspect the needle: Start by ensuring that you have the right needle for your fabric. Different fabrics require different needle sizes. A dull or bent needle can cause tension issues. So, it’s essential to replace it if needed. Remember to always insert the needle with the flat side facing the back.

- Check the threading: Make sure that you have properly threaded your sewing machine. Incorrect threading can lead to tension problems. Follow the threading guide provided by your machine’s manufacturer and double-check that the thread is securely in place.

- Adjust the tension settings: Most sewing machines have a tension dial or control that allows you to adjust the thread tension. Begin by setting the dial to the recommended middle position. Start sewing a test fabric scrap to see if the tension is balanced. If the thread loops appear on the top fabric, the tension is too loose. If they appear on the bottom fabric, the tension is too tight. Gradually make adjustments until you achieve even stitches.

- Experiment with different thread weights: If you’re still experiencing tension issues, try using a different thread weight. Sometimes, a heavier or lighter thread can make a significant difference in the tension.

Remember, practice makes perfect. It might take a few attempts to find the ideal needle and thread tension for your project. Take your time, stay patient, and don’t get discouraged. Your sewing machine is a versatile tool, and with a little tweaking, you’ll be stitching like a pro in no time!

Continue reading the article to discover more troubleshooting tips and tricks for common sewing machine problems.

Cleaning and Maintaining Your Machine

Keeping your sewing machine clean and well-maintained is essential for its longevity and optimal performance. Regular maintenance not only prevents issues but also ensures that your machine runs smoothly for all your sewing, embroidery, and crafting projects. Here are a few tips to help you keep your machine in top shape:

1. Clear the Fabric and Thread

After each sewing session, it’s important to remove any leftover fabric pieces and bits of thread from your machine. Use a small brush or a handheld vacuum cleaner to gently remove the debris. Clearing the fabric and thread prevents them from getting tangled in the moving parts of your machine, which can affect its performance.

2. Oil Your Machine

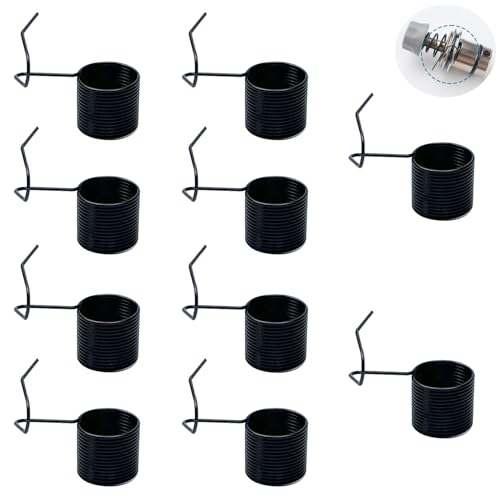

To keep your sewing machine running smoothly, it’s essential to oil it regularly. Refer to your machine’s manual for specific instructions on where and how to oil it. Generally, you’ll need to apply a few drops of sewing machine oil to specific points, such as the bobbin case and the moving parts. Regular oiling reduces friction, prevents rust, and ensures that your machine operates without any hiccups.

3. Replace Needles Regularly

A dull or damaged needle can cause skipped stitches, fabric pulls, and tension issues. To avoid these problems, make sure to replace your needle regularly. As a general rule, it’s recommended to change your needle after every 8-10 hours of sewing or after completing a project. Using the correct needle for the fabric you’re sewing on is also crucial. Refer to the needle size chart in your machine’s manual to choose the right needle for your specific fabric type and weight.

Remember, a well-maintained sewing machine is a happy sewing machine! So, make it a habit to clean your machine after each use, oil it regularly, and replace the needles when necessary. By following these simple steps, you can ensure that your machine operates at its best and helps you create beautiful projects for years to come.

Seeking Professional Help

While it’s great to be able to troubleshoot and handle most sewing machine issues on your own, there may come a time when you encounter a problem that requires professional assistance. Whether you’ve tried all the DIY solutions and still can’t seem to get your machine running smoothly, or you simply don’t feel confident enough to tackle the issue yourself, seeking the help of a professional can be a wise decision. Here are a few reasons why consulting an expert can be beneficial:

- Technical Expertise: Professional sewing machine technicians have extensive knowledge and experience working with a wide range of makes and models. They have the technical know-how to identify and diagnose complex problems that may not be easily recognizable to inexperienced users. By consulting a professional, you can ensure that your machine receives the expert attention it needs.

- Specialized Equipment: Sewing machine repair shops are equipped with specialized tools and equipment that may not be readily available to you at home. These tools can help the technician accurately analyze and fix intricate issues that may be affecting your machine’s performance. A professional will have the necessary resources to disassemble, repair, and reassemble your machine properly.

- Time and Effort: Some sewing machine problems can be time-consuming and frustrating to diagnose and fix on your own. By seeking professional help, you can save yourself the headache and stress of trying numerous solutions without success. A qualified technician can quickly assess the problem and provide a reliable solution, saving you time and effort in the long run.

- Peace of Mind: Sometimes, the peace of mind that comes with knowing your sewing machine is in capable hands is worth the cost of professional assistance. Rather than worrying about potentially causing further damage or voiding any warranties, you can trust that the technician will skillfully repair your machine and have it running smoothly again.

Conclusion

By following the practical solutions provided in this article, you can successfully troubleshoot and resolve common tension problems with your sewing machine. Remember to check and adjust the needle and thread tension step-by-step, ensuring that you are using the correct needle for your fabric and properly threading the machine. If tension issues persist, don’t hesitate to experiment with different thread weights to find the optimal combination.

In addition, maintaining your sewing machine is crucial for its optimal performance and longevity. Regularly clear fabric and thread debris, oil the machine, and replace needles as needed. These simple maintenance tasks can go a long way in preventing future problems and ensuring smooth sewing sessions.

If you find yourself in a situation where you need technical expertise or access to specialized equipment, don’t hesitate to seek professional help. Consulting an expert can save you time and effort, as well as provide peace of mind knowing that your sewing machine is in capable hands.

With these solutions and maintenance tips, you’ll be able to enjoy hassle-free sewing and get the most out of your machine. Happy sewing!