Are you struggling with your sewing machine? It might be time to check if your needle is blunt. A blunt needle can cause all sorts of issues, from skipped stitches to thread breakage. But how can you tell if your sewing machine needle is blunt? In this article, we’ll explore some telltale signs that indicate it’s time to replace your needle. So, grab your sewing machine and let’s get started!

When was the last time you changed your sewing machine needle? If it’s been a while, it’s worth checking if your needle is blunt. A blunt needle can lead to uneven stitches and fabric damage. In this article, we’ll show you how to determine if your sewing machine needle is blunt, so you can keep your projects looking professional and avoid unnecessary frustration. Let’s dive in and learn how to spot a blunt needle!

Importance of a Sharp Sewing Machine Needle

A sharp sewing machine needle is essential for achieving professional-looking results in your sewing projects. Here are a few reasons why it’s important to keep your needle sharp:

1. Stitch Quality

The condition of your sewing machine needle directly affects the quality of your stitches. When the needle is blunt, it can cause skipped stitches, uneven stitches, or fabric damage. This can result in a messy and unprofessional-looking final product. By using a sharp needle, you’ll achieve clean and precise stitches.

2. Thread Breakage

Using a blunt needle can also lead to frequent thread breakage. When the needle is dull, it may struggle to pierce through the fabric smoothly, causing the thread to fray or snap. This not only slows down your sewing progress but can also be frustrating to deal with. A sharp needle helps prevent unnecessary thread breakage and saves you time and frustration.

3. Fabric Preservation

A blunt needle can damage the fabric by creating larger and more visible holes. This is especially true when working with delicate fabrics like silk or chiffon. These visible holes can affect the overall appearance of your project, particularly if you’re working with patterned or fine fabrics. By using a sharp needle, you minimize the risk of fabric damage and preserve the integrity of your fabric.

4. Machine Performance

A sewing machine with a blunt needle may strain and struggle to stitch smoothly. This can put unnecessary stress on your machine’s motor and reduce its overall performance. By regularly checking and replacing the needle, you ensure that your machine operates smoothly, prolong its lifespan, and avoid costly repairs.

Remember, the sharpness of your sewing machine needle is crucial in achieving excellent stitching results, preventing thread breakage, preserving your fabric, and maintaining your machine’s performance.

Signs of a Blunt Sewing Machine Needle

When it comes to sewing, using a sharp needle is crucial for achieving professional-looking results. A blunt needle can cause a range of issues like skipped stitches, thread breakage, fabric damage, and strain on the machine’s performance. To avoid these problems, it’s important to know the signs of a blunt sewing machine needle. Here are a few key indicators to look out for:

1. Skipped Stitches

One of the most common signs of a blunt needle is skipped stitches. If you notice that your machine is not forming stitches consistently or there are gaps in the stitching, it’s time to check your needle. A blunt needle may fail to penetrate the fabric properly, resulting in incomplete or skipped stitches. This can greatly affect the overall quality and durability of your project.

2. Thread Breakage

Experiencing frequent thread breakage? A blunt needle could be the culprit. A dull needle can weaken the thread, causing it to snap more easily during the sewing process. If you find yourself constantly rethreading your machine or dealing with frustrating thread breaks, it’s a clear indication that you need to replace your needle.

3. Fabric Damage

Is your fabric showing signs of damage while sewing? A blunt needle can cause snags, pulls, or even tears in your fabric. It’s important to inspect the texture of your fabric after sewing a few stitches. If you notice any signs of damage or the fabric seems to fray easily, it’s time to swap out your needle for a sharper one.

« Discover the Ultimate Sewing Kit Must-Have Every Fashionista Needs for Stunning DIY Creations

Discover the Ultimate Beginner’s Sewing Project: Sewing Made Easy with These Foolproof DIY Ideas »

4. Reduced Machine Performance

A dull needle can put extra strain on your sewing machine, leading to decreased performance. If you notice that your machine is making unusual noises, vibrating excessively, or just not running as smoothly as it used to, a blunt needle may be to blame. Taking care of your needle will not only improve the quality of your sewing but also extend the life of your trusty machine.

The Importance of Regular Needle Maintenance

Taking care of your sewing machine needle is essential for achieving professional-looking results in your sewing projects. A well-maintained needle ensures clean and precise stitches, prevents thread breakage, preserves the fabric, and maintains the performance of your machine. Neglecting needle maintenance can lead to a host of issues and frustrations that can easily be avoided.

Here’s why regular needle maintenance is crucial:

1. Clean and Precise Stitches

A sharp needle is the key to achieving clean and precise stitches. When the needle is blunt, it can cause skipped stitches, resulting in gaps in your seam or design. By regularly checking and replacing the needle, you ensure that every stitch is perfectly formed, giving your project a professional finish.

2. Prevents Thread Breakage

Using a blunt needle puts strain on the thread, increasing the likelihood of breakage. This can be frustrating and time-consuming, causing interruptions in your sewing process. By keeping your needle sharp, you minimize the risk of thread breakage, allowing you to sew smoothly and efficiently.

3. Preserves the Fabric

A blunt needle can damage delicate and expensive fabrics. When the needle becomes dull, it can snag the fabric, leading to pulls, tears, or fraying. By maintaining a sharp needle, you protect your fabric investment and ensure that your finished projects look their best.

4. Maintains Machine Performance

A sewing machine works best when equipped with a sharp needle. A blunt needle can put unnecessary strain on the machine’s motor and moving parts, reducing its performance and potentially causing damage. Regular needle maintenance not only keeps your stitches looking great but also prolongs the life of your machine.

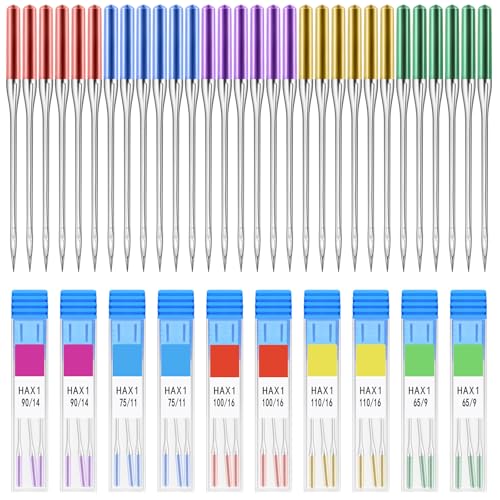

How to Test if Your Sewing Machine Needle is Blunt

Now that you understand the importance of regular needle maintenance, let’s dive into how you can tell if your sewing machine needle is blunt. By being able to identify a dull needle, you can take immediate action to replace it and ensure optimal stitching results.

Check for Skipped Stitches

One of the first signs that your sewing machine needle is blunt is when you start experiencing skipped stitches. If you notice that the needle is not fully piercing through the fabric or if the stitches are uneven, it’s a clear indication that your needle needs to be replaced. Keep in mind that skipped stitches can also be caused by other issues, such as incorrect threading or tension, so it’s important to eliminate those possibilities before concluding that the needle is blunt.

Observe for Thread Breakage

Another telltale sign of a blunt needle is frequent thread breakage during sewing. If you find that your thread is constantly snapping or fraying, it’s time to examine your needle. A dull needle doesn’t create clean punctures in the fabric, leading to resistance and tension on the thread, which can ultimately result in breakage. Remember to check your thread tension and use high-quality thread as well, as these factors can also contribute to thread breakage.

Examine Fabric Damage

When your sewing machine needle is blunt, it can cause visible damage to your fabric. Take a closer look at your stitches and inspect for any signs of fabric snagging, pulling, or fraying. Blunt needles can push fibers aside rather than piercing through them cleanly, resulting in a compromised fabric surface that may be weakened and prone to unraveling. If you notice any fabric damage, replace your needle promptly to avoid further harm.

Assess Machine Performance

Lastly, pay attention to your sewing machine’s performance as you sew. If you notice that your machine is making unusual sounds, such as clunking or clattering, it could be a sign that your needle is blunt. A dull needle can put strain on the machine’s mechanisms, causing it to operate less smoothly. Additionally, a blunt needle may result in a slower sewing speed or inconsistent stitch formation. So, if you notice any changes in your machine’s performance, consider checking and replacing your needle.

By following these steps, you can easily test if your sewing machine needle is blunt. Remember, a sharp needle is crucial for achieving professional-looking results in all your sewing projects. Regularly checking and

Conclusion

Regular needle maintenance is crucial for achieving professional-looking results in your sewing projects. By using a sharp needle, you can ensure clean and precise stitches, prevent thread breakage, preserve your fabric, and maintain your machine’s performance.

Neglecting needle maintenance can lead to a range of issues, including skipped stitches, thread breakage, fabric damage, and strain on your machine’s performance. To avoid these problems, it’s important to regularly check and replace your needle.

By following the tips provided in this article, you can easily test if your sewing machine needle is blunt. Look out for signs such as skipped stitches, thread breakage, fabric damage, and poor machine performance.

Remember, taking the time to check and replace your needle regularly will result in high-quality stitches, prevent thread breakage, preserve your fabric’s integrity, and extend the lifespan of your sewing machine. So, make needle maintenance a priority in your sewing routine for the best sewing experience possible. Happy sewing!