Choosing the right sewing machine needle for cotton can make a world of difference in your sewing projects. Whether you’re a seasoned seamstress or just starting out, understanding needle sizes is crucial for achieving those perfect stitches.

Cotton is a versatile fabric, but it requires the right needle to prevent snags and ensure smooth sewing. Dive into this guide to learn which needle size will help you create flawless cotton garments and crafts every time.

Understanding Sewing Machine Needles

Understanding needle types enhances your sewing experience. Choosing the right needle for cotton fabric ensures smooth, high-quality stitches.

Types of Sewing Machine Needles

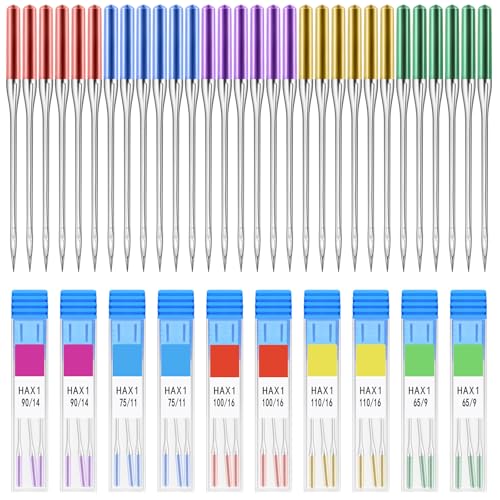

Selecting the correct needle type is crucial. Universal needles, designed for most fabrics, including cotton, come in sizes 60/8 to 90/14. Sharps (microtex) needles, with fine, pointed tips, ideal for tightly woven fabrics like high-quality cotton, range from 60/8 to 90/14. Quilting needles, perfect for multiple fabric layers, including cotton batting, come in sizes 75/11 to 90/14. Embroidery needles, featuring larger eyes to prevent thread breakage, work well with cotton embroidery floss in sizes 75/11 and 90/14.

Key Characteristics of Needles

Examining needle characteristics ensures optimal results. Needle size, indicated by two numbers (e.g., 80/12), reflects diameter (European/American). Smaller numbers suit lightweight cotton, while larger numbers handle heavyweight cotton. Needle point type, such as sharp or ballpoint, influences fabric penetration. Sharp points work best for woven cotton fabrics. Needle eye size accommodates thread types; larger eyes prevent friction damage to threads. Shank design, typically flat or rounded, ensures proper machine fitting.

Choosing the Right Needle for Cotton

Selecting the correct needle is crucial when sewing cotton fabric. It affects stitch quality and fabric integrity.

Factors Affecting Needle Choice for Cotton

Several factors influence needle choice for cotton fabric:

- Fabric Weight: Coordination between needle size and fabric weight is essential. Lightweight cotton (e.g., voile, lawn) requires a smaller needle, whereas heavyweight cotton (e.g., canvas, denim) necessitates a larger one.

- Thread Type: Matching thread thickness to needle size ensures smooth threading and prevents breakage. Finer threads pair well with smaller needles, while thicker threads suit larger needles.

- Sewing Machine Type: Compatibility with your sewing machine is a must. Some machines perform better with specific needle brands or types. Check your manual for guidance.

- Project Specifications: The nature of the project may require specific needle types. For instance, quilting cotton fabric generally requires quilting needles, while embroidery projects benefit from embroidery needles.

Recommended Needle Sizes for Cotton Fabric

Understanding needle sizes helps you achieve precise stitches on cotton fabric:

| Fabric Type | Needle Size (US) |

|---|---|

| Lightweight Cotton | 8/60 – 10/70 |

| Medium-weight Cotton | 11/75 – 14/90 |

| Heavyweight Cotton | 16/100 – 18/110 |

A universal needle works for general sewing, while sharps needles are ideal for detailed work on tightly woven cotton. Quilting and embroidery needles suit specific projects, providing the right sharpness and strength.

By considering fabric weight, thread type, sewing machine compatibility, and project specifications, you can select the perfect needle for your cotton fabric. This ensures high-quality, smooth stitches for all your cotton sewing projects.

How Needle Size Affects Your Sewing Quality

Choosing the right needle size is vital for ensuring high-quality sewing results on cotton fabric. The needle size impacts many aspects of your sewing project, from stitch quality to overall fabric appearance.

Impact on Stitch Quality

A proper needle size ensures consistent, even stitches on your cotton fabric. Using the correct size allows for smooth penetration through the fabric, preventing skipped stitches or thread breaks. For lightweight cotton, size 70/10 or 80/12 needles work well, while medium weights benefit from 80/12 to 90/14 needles. Heavy cotton fabrics perform best with 90/14 to 100/16 needles.

Common Issues with Incorrect Needle Sizes

Incorrect needle size can cause problems like puckering, skipped stitches, and fabric damage. A too-small needle may struggle to move through thick cotton, causing the thread to break or jam. Conversely, a too-large needle can leave visible holes in lightweight cotton, ruining your project’s finish and integrity. Always match your needle size to the fabric weight to avoid these issues.

Tips for Sewing Cotton Fabrics

Mastering the sewing of cotton fabrics ensures high-quality results in your projects. Employing the right techniques and practices enhances both the sewing process and final product.

Adjusting Tension and Stitch Length

Adjust tension settings to match cotton fabric characteristics. Proper tension prevents puckering and ensures even stitches. For medium-weight cotton, set the tension at a moderate level.

Stitch length adjustments also impact fabric handling. Use a 2.5 to 3 mm stitch length for a balanced and smooth finish on cotton fabrics. Longer stitches, like 4 mm, work well for basting or gathering.

Best Practices for Needle Maintenance

Regular needle checks and replacements maintain stitch quality and fabric integrity. Replace needles after 8-10 hours of sewing or when you notice skipped stitches or fabric snags.

Store needles in a dry, organized space. Use needle cases to prevent damage and ensure easy identification of different types and sizes.

Conclusion

Choosing the right sewing machine needle for cotton fabric is key to achieving beautiful, high-quality stitches. By considering factors like fabric weight, thread type, and your sewing machine’s compatibility, you can ensure smooth, hassle-free sewing. Remember, matching the needle size to your fabric weight helps prevent common issues like puckering and skipped stitches.

« Discover the Secret to Fixing Sewing Machine Timing: Say Goodbye to Skipped Stitches and Thread Breakage

7 Shocking Reasons You Should Start Caring for Your Sewing Machine Today »

Don’t forget to adjust your tension settings and stitch length to suit your cotton fabric. Regular needle maintenance is also crucial, so make it a habit to check and replace your needles after 8-10 hours of sewing. Keep them stored properly in a dry, organized space using needle cases.

With these tips and a bit of practice, you’ll be well on your way to mastering cotton sewing projects. Happy sewing!